| |

| Engineering Design |

|

Design is the most important part and feature of any manufactured products. ALLZAFLEX’s design incorporates quality built than quality maintained. The design department at Allzaflex has qualified and experienced engineers to achieve the best and optimized design for the each customer’s specific requirement.

At Allzaflex, design of product involves customers equally. While the customer designs the higher level systems and subsystems, Allzaflex designs the expansion joint for them. With involvement of customer from the beginning of the design process, the probability of the end product meeting the customer’s requirement is greatly increased.

Allzaflex has successfully designed bellows for some of the most critical applications which include cryogenics, steel plants, cement plants, nuclear reactors, Indian Navy, hot blast furnace and many more. |

|

| |

|

| Manufacturing Facilities |

|

| Allzaflex believes better infrastructure gives better workability which results in better quality. It has adequate facilities for manufacturing largest size expansion joint with most stringent quality control. |

| |

| Manufacturing Floor Area |

21,000 Sq Feet |

| Total Land Area |

30,000 sq. Feet. |

| Electric Overhead Traverse Capacity |

5 tons. |

| Maximum Hook Height |

30 feet |

| Plate Roll |

1250mm x 12mm |

| Hydraulic Press |

150 tons |

| Automatic Forming Machine |

upto 500 NB |

| Mechanical Forming Machine |

25 NB to 8000 NB and above |

| Die Press Fforming Machine |

NO BAR.(For rectangular expansion joint) |

| Movable Gantry |

5 ton x 6 meter height. |

| Plasma Cutting Machine |

30 mm |

| Field Installations |

|

| Painting and Finishing Facilities |

|

|

| |

|

|

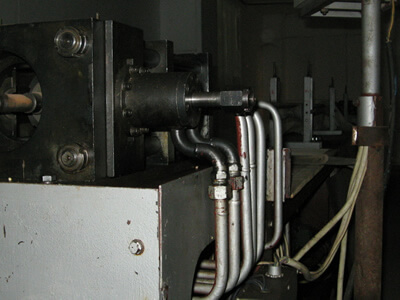

| Hose crimping machine |

|

| |

|

| Crimp upto 6" 4 SP hoses |

Crimp upto 2" 4 SP hoses |

|

|

| |

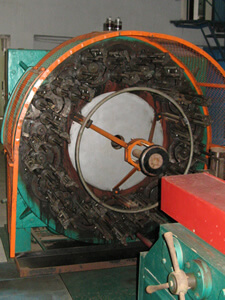

| Corrugated hose forming machine |

|

| |

|

|

|

|

|

| |

| Bobbin filling |

Braiding machine |

|

|

| |

|

|

|

|

|

|

| |

|

| |

| |

|